At the start of the pandemic, everything shut down and school became remote; Without access to our lab, our robotics program faced a dire prospect: shut down until school was back in person.

My co-leads and I felt responsible for preserving the momentum and expertise we had built. We first created an online training program for rookies and I taught several modules. However, without hands-on work with real machines, interest and engagement remained low. It became clear that when we emerged from the pandemic, we would be inadequately prepared.

What could we do that was as exciting as building a robot, but could be done at home? Then an aha moment struck—who doesn’t like flying (and crashing) drones?

My co-leads and I realized that we could remotely design, then co-opt printing components across our own network of home printers. To further enable at-home fabrication, I designed and built a low-cost Computer Numeric Control (CNC) router with 3D printed hard-plastic parts and purchased metal components that could precision cut wood, plastic, and metal in my garage. Which you can read more about here!

We created a detailed, FRC-Esque handbook and built example drones to standardize components, assess their capabilities, and troubleshoot errors that may discourage participants.

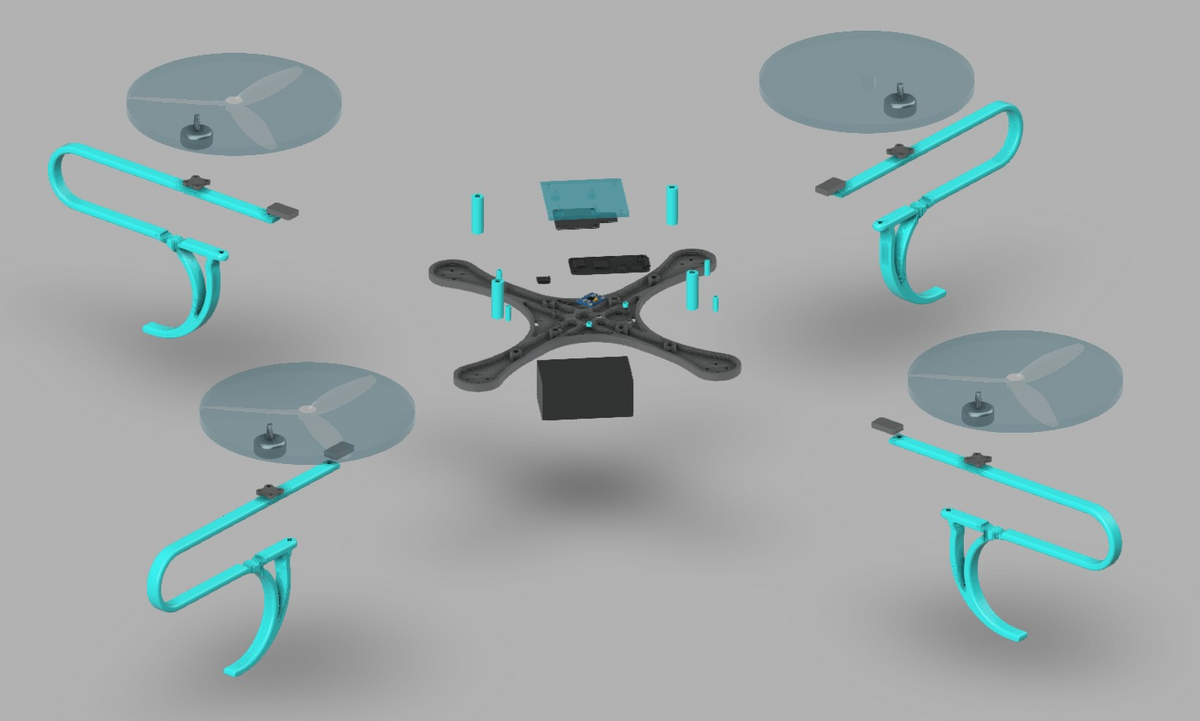

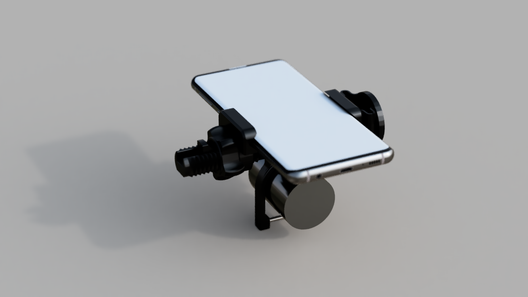

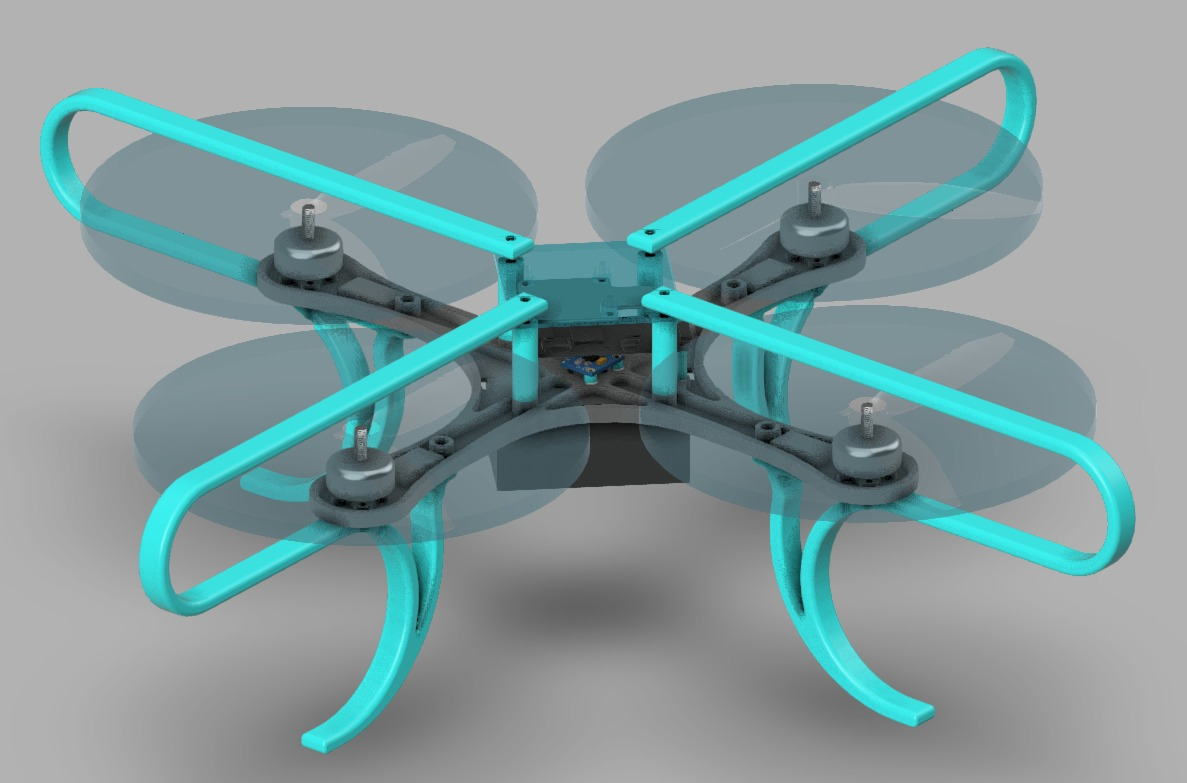

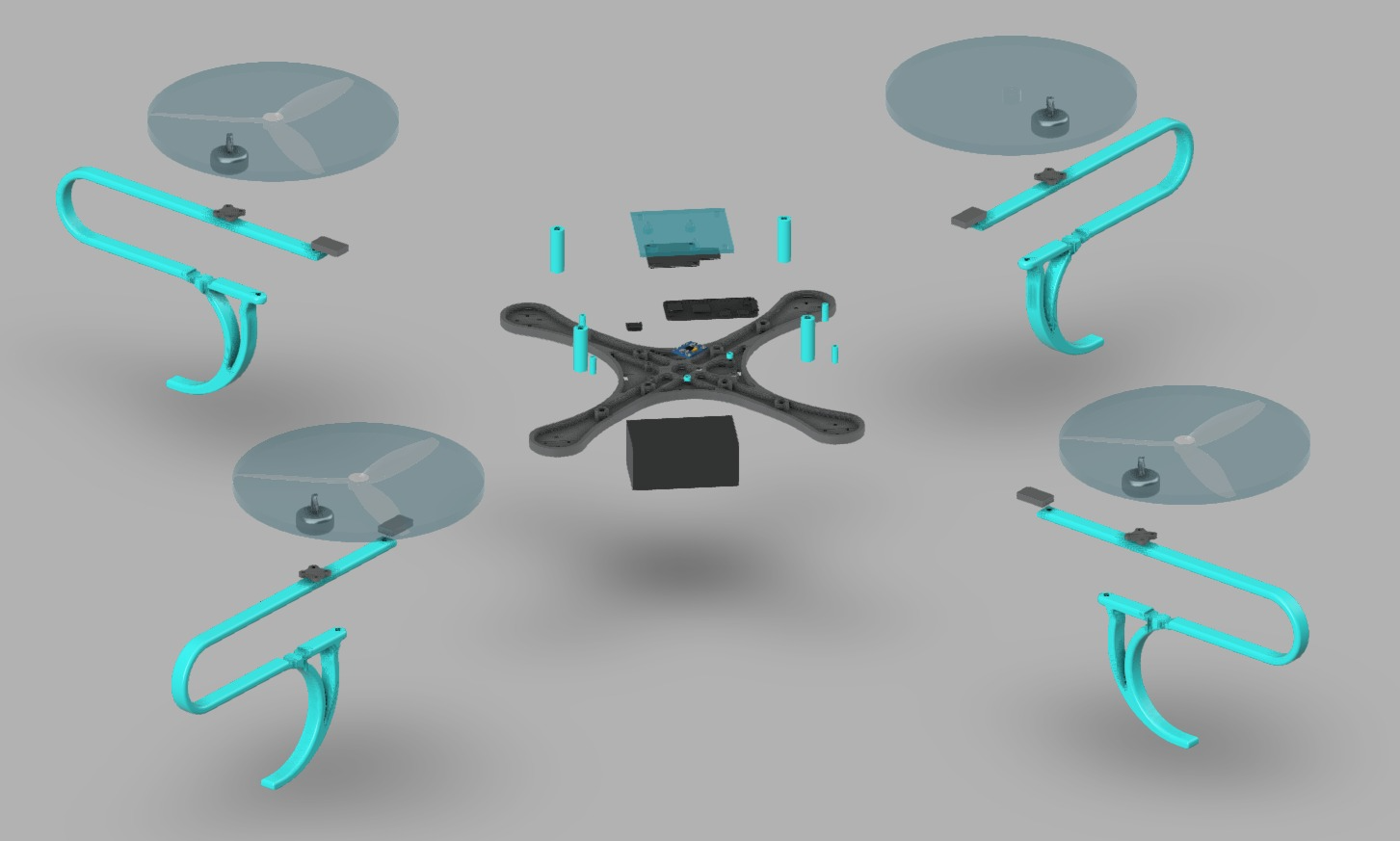

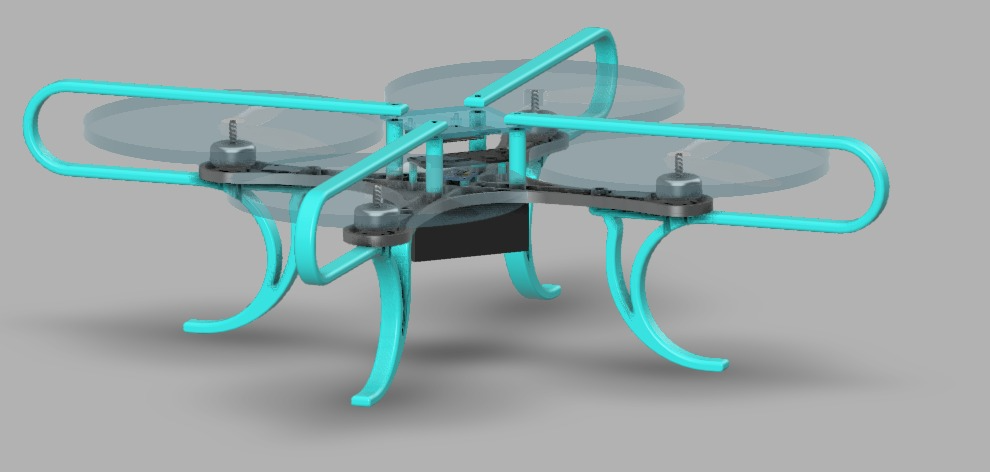

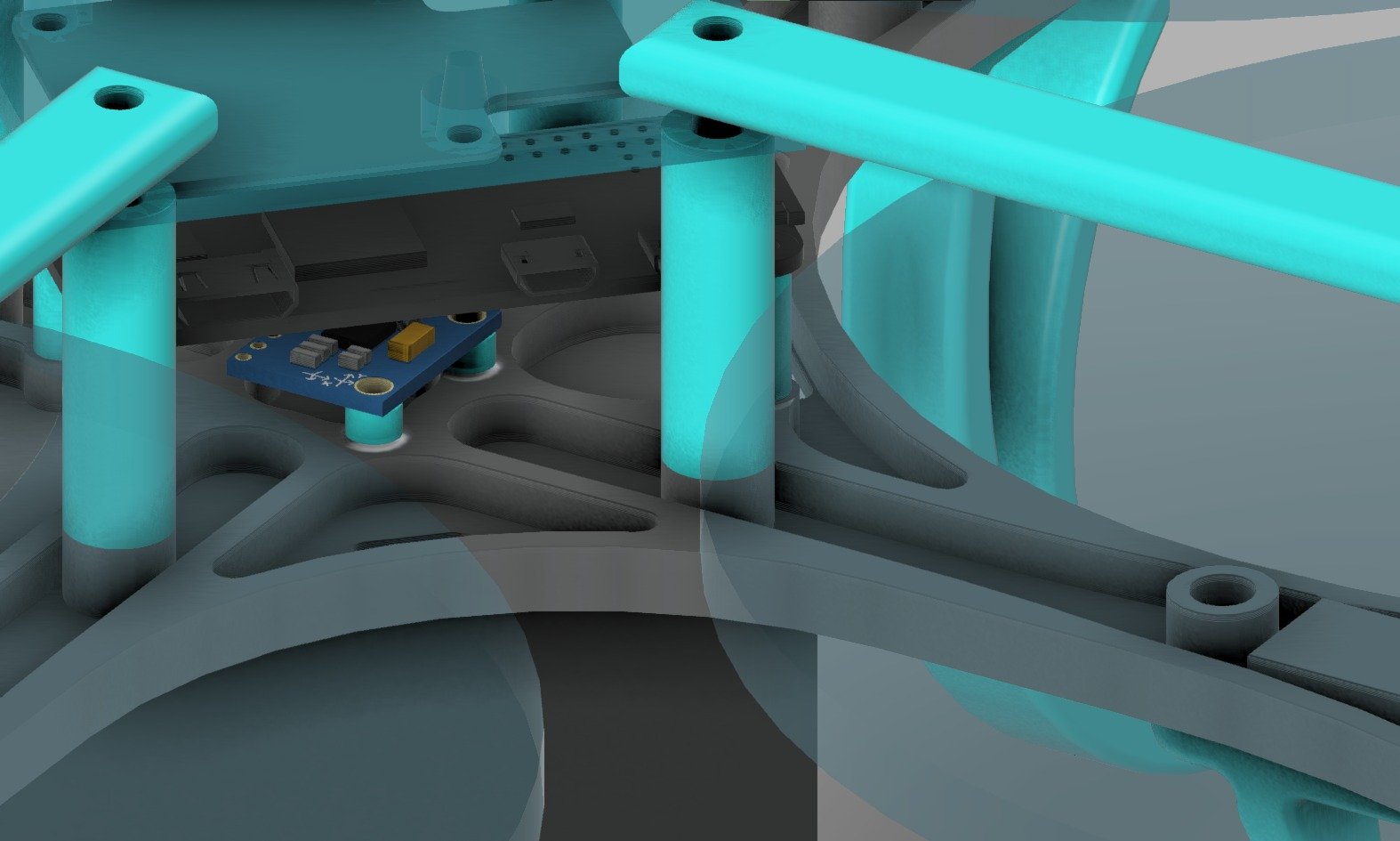

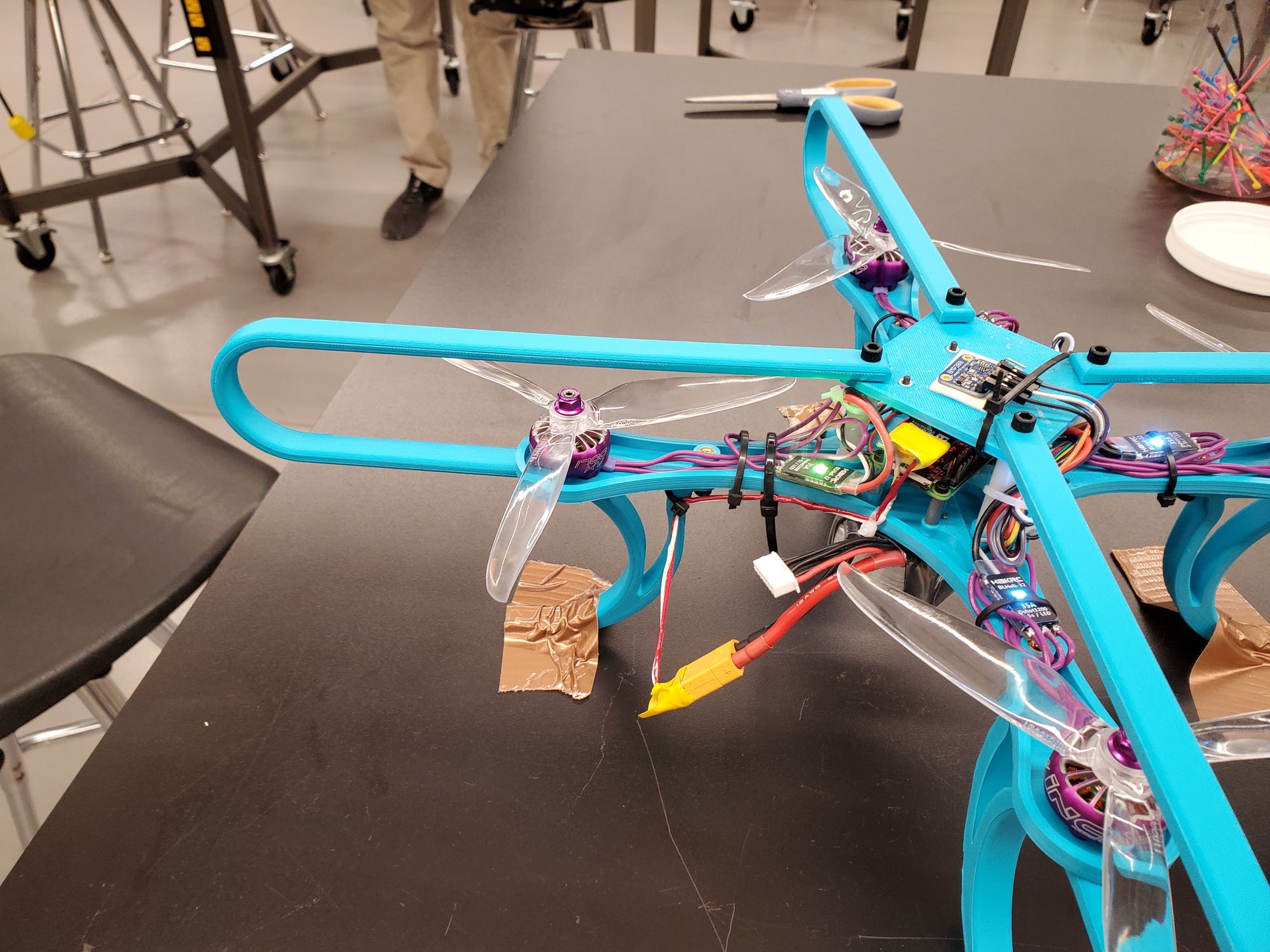

Here are some screenshots of the example drones that I designed and built with a co-lead of mine.

We reviewed designs, remotely manufactured parts on our personal printers, and managed components for assembly and testing.

While we ultimately weren't able to host a competition, the students learned a tremendous amount during the designing, got hands-on experience during a global pandemic, and when we were back in the lab, a few of the groups were able to have working and flying drones!

The drone leadership team!

Sometimes things didn't go towards plan...especially w/ the entire school administration watching...